Inside the workshops, it is often necessary to use different types of fluids simultaneously, intervening on different vehicles under repair.

Inside the workshops, it is often necessary to use different types of fluids simultaneously, intervening on different vehicles under repair.

This is one of the main reasons why having an oil distribution system, which can also help to increase efficiency and productivity.

How to choose the most suitable one? Let's talk about this in the article!

Why is an oil distribution system necessary in the workshop?

Every car, truck, or heavy-duty vehicle workshop needs dedicated systems to manage lubricating oils and technical fluids, both new and used (antifreeze, windshield washer fluids, ADBlue, water, and compressed air), that will avoid waste, in terms of time and revenue, thanks to an accurate and timely billing 100% corresponding to material consumption.

Monitoring oils and fluids and transporting them, from storage tanks to the point of use, are procedures that need time and resources. If you do not have an automated system, technicians often have to move from one area of the workshop to another, carrying very heavy drums, making operations chaotic and potentially risky.

The implementation of a centralized dispensing system is a key element in ensuring greater efficiency and safety in the workshops daily operations, whatever the volume of dispensing they have to handle.

The most modern oil dispensing systems -known as pumping systems- perform several functions:

- they dispense lubricating fluids from the "new oil" room to individual workstations

- they manage the disposal of used oils

- they manage the distribution of other technical fluids

This allows to:

- improve stock management

- speed up filling and refilling operations

- contain and optimize costs

The most efficient and correctly sized systems, when needed, also optimize the space occupied by equipment, making the work area neat and tidy.

The elements of an oil distribution system

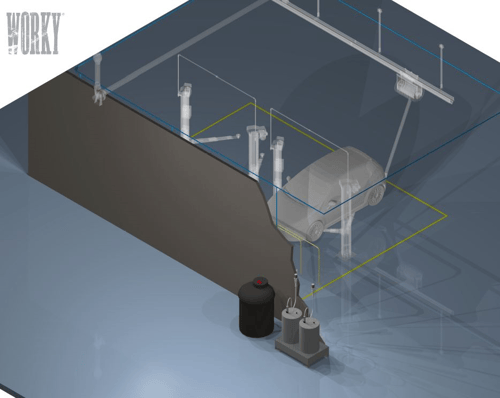

Distribution systems are normally located in the oil room and may consist of different elements, depending on the workshop's needs in terms of the quantity of fluids distributed daily.

In generala distribution is made of:

- a central hub for dispensing fluids with a variable number of reels

- a centralized location for pumping fluids, i.e., an oil room with various tanks and vats, equipped with anti-overflow indicators

- appropriately sized extraction hoses to guarantee a constant flow in line with the company's needs

- containers for exhausted oils storage

The plant can then be completed by:

- switchboards to control the filling level of fluid and new oil tanks, with anti-bubble alarm

- switchboards with level switches for used oils, which prevent overflow before the tank is completely full

By integrating the facilities with computerized monitoring systems it will be possible to:

- reduce polluting waste

- avoid waste and shortages

- contain costs

- increase profits

- comply with environmental protection regulations

This is possible thanks to a system of solenoid valves and flow meters, whose movements (each individual dispensing of oil) are recorded by software within the system.

Dispensing systems, in addition to the distribution of technical fluids, can also deliver electricity and compressed air directly to the working area.

The best systems have personalized structures and components that can cope with the different workshop needs.

Let's have a look to some of them.

Multifunctional systems

If the workshop's need is to accommodate several different utilities, a multifunction dispensing system is the best solution.

In fact, a multifunction system can be customized with multiple hose reels, each dedicated to a specific fluid or power.

In this way, it is possible to optimize space and to make operations much more efficient, since technicians have everything at hand, in a single structure, with no need for additional utilities.

There are several solutions on the market that differ in:

- the number of utilities

- the size of the structure

- whether or not electrical outlets are present

Guns

The terminal part of a fluid distribution system is almost always a gun, i.e., a valve that, through a trigger, lets the fluid through and is one of the most customizable components.

In fact, depending on the specific use and the fluid to be distributed, they can have different shapes, materials and sizes. In addition, the presence of a digital flowmeter with pre-selection means that the amount of fluid dispensed is always under control.

Hose reels

In a dispensing system, the hose must be the right length to enable the operator to reach the desired point. Hose reels allow to shorten or extend the hose so that it is always available where needed. Again, there are different types of hose reels depending on the dispensing use and type. The most common models are open reels and hooded reels, which are equipped with a special shell that provides greater protection.

At WORKY, we can take care of every aspect involving oil distribution, from design to implementation, depending on the needs of your workshop.

If you need information, do not hesitate to contact us: book a free, no-obligation consultation!