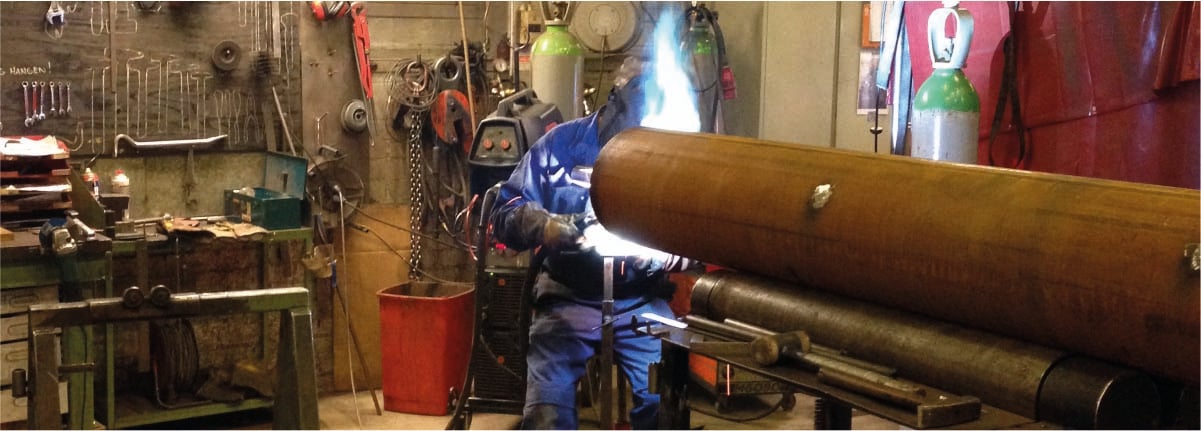

If your company operates in the mechanical, steel or general manufacturing sector, you will be well aware that welding activities generate a large amount of fumes every day, which make the working environment unhealthy and safe for operators.

If your company operates in the mechanical, steel or general manufacturing sector, you will be well aware that welding activities generate a large amount of fumes every day, which make the working environment unhealthy and safe for operators.

So, if you are looking for welding fumes extraction systems to solve the problem, read on to discover some useful tips!

Why a welding fumes extraction systems is necessary in your company

Welding is a common activity in many industries and workshops and often lasts for many hours, generating fumes and dust that contain substances harmful to the health of the people working in close contact with it. The nature of these fumes depends on the type of metal used, but they all contain tiny airborne particles that, if inhaled, can cause respiratory problems and an increased risk of cancer.

Modern welding fumes extraction systems intervenes at the source of the problem, be it a welding bench or an orbital sander, eliminating harmful gases and elements where they are produced, ensuring the healthiness of the workplace. In fact, we must remember that a safe and healthy working environment has a significant impact on the productivity and efficiency of a company and the quality of its work.

The fumes that are dispersed in the work area, in addition to being breathed in by the operators, are deposited on walls, floors and objects, making the area unliveable and risking the success of the work.

How to choose the most suitable smoke extraction system

Each system must be conceived and designed on the basis of the company's specific needs, taking the following elements into account:

- workspaces and zone configuration

- the types of activities for which they will be used

- the frequency of processing

- the number of suction points required

It is important that the equipment, as well as having a suction power appropriate to the characteristics and needs of the company, does not get in the way of the operators' work!

This is why it may be useful to ask the supplier for a 3D design of the working area before making a decision on the purchase of the welding fumes extraction systems; this will give a clear view of the layout of the equipment and give a realistic idea of the positioning of the machines and the overall dimensions.

Welding fume removal systems

Welding fume extraction systems can be fixed or mobile. Let's see what distinguishes them.

Fixed welding fumes extraction systems

Fixed systems suck fumes from the work area and expel them to the outside. They can have cartridge or pocket filters and are ideal when you have a specific and designated welding area, where one operator at a time only performs that task.

Fixed systems can be equipped with articulated arms, available in different lengths, hoods with customised dimensions, or suction benches. The latter allow fumes to be captured during operations performed on the work surface, without active intervention by the operator, and can also be used as normal workbenches, so as to optimise space.

Mobile welding fumes extraction systems

Mobile extraction systems, being mounted on wheeled units, are very convenient to move to different areas of the workshop. They consist of a fan, filters and articulated arms of different lengths to conveniently get where you need them.

They are the ideal solution when there is no designated welding area in the company, but there is a need to move around frequently.

As far as mobile welding vacuum cleaners are concerned, WORKY offers various solutions including:

SMOBIPLUS, a welding fume extractor ideal for light and infrequent welding jobs;

SMOBIMAX, a mobile solution but suitable for heavier, medium-duration welding tasks; it can be equipped with one or two arms

When deciding to invest in modern and innovative welding fumes extraction systems, it is important to choose a versatile and customised solution that fits the company's needs both today and tomorrow.

WORKY is a completely Italian production company, based in the heart of the Emilian Motor Valley, which stands out for the very high quality of its products.

One of the company's strengths is the development of tailor-made projects for each customer.

The highly qualified after-sales personnel have a great deal of experience not only in dealing with unforeseen events on site, but also in the phase preceding assembly.

Do you want to know more or need clarification? Our experts are at your disposal for all your needs: book a free consultation!