Designing a fume extraction system means finding the perfect solution for a specific need, taking into account all the characteristics of the location, the activities that take place there and the pollutant production methods. Let's see how to take into account all these variables for the correct design of a fume extraction system in an industrial context, and what are the possible configurations.

Designing a fume extraction system means finding the perfect solution for a specific need, taking into account all the characteristics of the location, the activities that take place there and the pollutant production methods. Let's see how to take into account all these variables for the correct design of a fume extraction system in an industrial context, and what are the possible configurations.

An extraction system is necessary and mandatory to protect the health of operators in all industrial contexts where welding and tin plating are routine. The correct design of the system leads to a series of further benefits:

- the workplace is more orderly, clean and comfortable

- production is leaner and faster

- the final product has a clearly superior quality.

But how is a fume extraction system designed? Let's find out with the WORKY team.

Designing a fume extraction system: the variables involved

The design of each fume extraction system begins with the evaluation of the objective variables relating to the type of industrial environment, the activities carried out and the fumes produced. More specifically, we must take into account:

- the room in which the extraction and filtering system will operate

- the number of workstations and their locations (for example, are they near or far from each other?)

- the type of production of the pollutant (fume), i.e. the methods of emission

- the size of the parts to be welded (for example: small household appliance components or long steel pipes)

- the welding or tin-plating frequency and their average duration.

On the basis of these variables, we will have, for example, the case of an industrial sector with many constantly used workstations where stainless steel parts are welded; or the case of a small manufacturing company, with a single workstation, where welding occasionally releases tin oxide emissions.

Efficient design guidelines

Thanks to the experience accumulated in the field, WORKY is able to provide a specialized service for the design of a fume extraction system, that is, for choosing the right system for different types of industrial realities.

Here are some application examples:

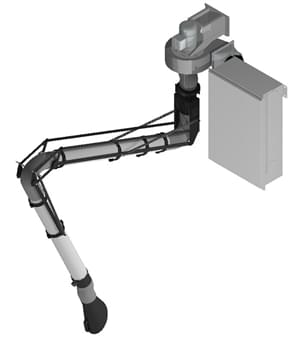

- For manufacturing companies where welding is frequent and on average intense, but always carried out in the same workstation, the ideal system is a kit with wall-mounted extractor and an extraction arm.

SPARK kits

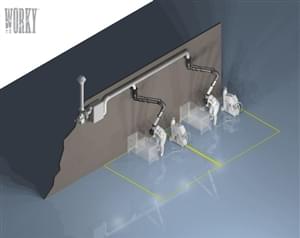

- For a carpenter where welding is a continuous operation and is carried out in several workstation, even simultaneously, the most efficient solution is a centralised wall system, with as many extraction arms as there are workstations.

Centralised permanent system

- For a production area where welding is carried out alternately in one or more workstation, the best choice is a portable wheeled fume extractor with 1 or 2 extraction arms.

SMOBIMAX-1B