08/03/2016

2 Minutes

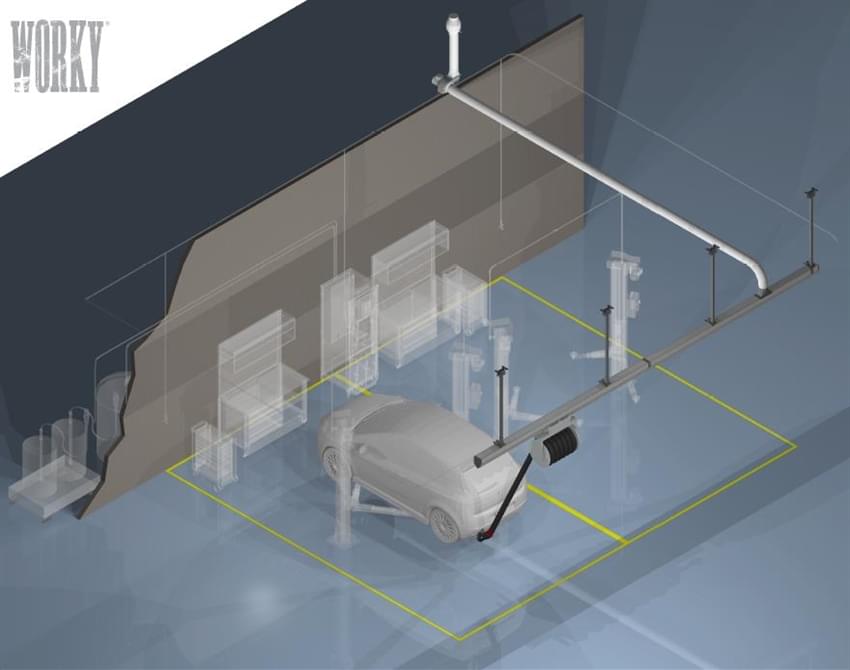

Anyone who works in a mechanical workshop or a car body repair shop knows only too well that, for a clean and healthy working environment, a good workshop exhaust fan proves to be an essential ally, including for complying with the applicable laws on matters of health and safety of employees.

Anyone who works in a mechanical workshop or a car body repair shop knows only too well that, for a clean and healthy working environment, a good workshop exhaust fan proves to be an essential ally, including for complying with the applicable laws on matters of health and safety of employees.

The fan is the heart of any extractor system and, as such, is one of the main tools in the fight against fumes and exhaust gas that a workshop has to deal with on a daily basis. Correct operation of this system, its efficiency and reliability, are therefore essential elements for working properly. But how can we assess the quality of a workshop exhaust fan?

Let’s take a look together at some of the most important parameters:

- Dimensions: first and foremost, we have to take into consideration that the ideal system is designed in proportion to the workshop where it is located, the volume of work it has to deal with each day, and the specific needs it has. Which is better, a fixed or a moveable system? To achieve the perfect solution, in any case what counts most is the professionalism of the supplier: an expert and adept manufacturer will be able to give advice on the workshop exhaust fan most suited to the specific needs of your situation.

- To ensure the longevity of a workshop exhaust fan system, it must be equipped with vibration suppression measures: WORKY supplies as standard with its fans a vast range of feet that cut vibration down to the minimum while the system is in use, ensuring quieter operation, greater mechanical efficiency and a longer fan life.

- Remote control: here too the accent is on efficiency. A modern system is designed to provide remote control operation of workshop exhaust fans by means of microswitches, Radio-frequency remote controls and a control panel. This kind of operation avoids the operator having to constantly move backwards and forwards to the fan, optimising his work considerably.

Considerations for outdoor use: in some circumstances a workshop exhaust fan system has to be installed outside the industrial unit. In this case, before purchasing any model, it is a good idea to check whether the manufacturer also has a means of protecting the fan’s electric motor. Outdoor installation exposes the motor to atmospheric conditions that could compromise its correct working operation.

Considerations for outdoor use: in some circumstances a workshop exhaust fan system has to be installed outside the industrial unit. In this case, before purchasing any model, it is a good idea to check whether the manufacturer also has a means of protecting the fan’s electric motor. Outdoor installation exposes the motor to atmospheric conditions that could compromise its correct working operation.

- Soundproofing: makers of exhaust fans know that life in the workshop is always very noisy, sometimes even chaotic, and that a fan certainly does nothing to help keep the workplace quiet. That’s why, when purchasing a workshop exhaust fan, it can be a good idea to enquire as to whether there is the option of soundproofing, either straight away or in the future. In this case too, check whether the manufacturer has soundproofing solutions that are compatible with the fan model purchased.