In manufacturing industries, frequent sanding operations are the cause of dust formation that can be hazardous to workers' health, affecting productivity.

In manufacturing industries, frequent sanding operations are the cause of dust formation that can be hazardous to workers' health, affecting productivity.

Installing state-of-the-art industrial dust extractors is therefore essential, but how to choose them? We discuss this in today's article!

The supplier's role in choosing industrial dust extractors

Deciding to invest in an industrial dust extractor is necessary to ensure maximum efficiency of the company and to comply with current regulations in terms of the healthiness of the work area.

Powdered filler, for example, is toxic and carcinogenic, especially for operators subject to prolonged exposure.

Moreover, if dust settles on the vehicle or object sanded before it is painted, the quality of the final work will be put at risk, resulting in the need to redo the job, wasting time and resources.

This is why installing state-of-the-art systems is critical!

How to know if you are relying on a competent supplier who knows how to design functional and effective facilities?

Not all Companies need the same extraction system. Each type of business has very specific requirements; hence the need for customised machinery.

Not only need of aspiration- which therefore depend on the types of work performed - but also of available spaces, standards to be met, structural, architectural and design needs.

In Companies where small and not very frequent work is carried out, for example, it will not be necessary to install industrial dust extraction systems with high extraction capacities.

Similarly, if the company needs to extract a large amount of dust, it will need machinery with high power.

Installing a system that is in line with the requirements, in order to avoid waste of time, resources and energy, is essential, to ensure efficiency and healthiness of the work area.

For that reason, it is necessary to rely on an experienced partner who knows how to design a system that meets the real needs of the enterprise, developing a tailor-made project.

In general, however, there are definite characteristics that an industrial extract cleaner should have in order to be considered modern and state-of-the-art. Let's look at them below.extraction

Industrial dust extractors: the must-have features

An industrial extract cleaner, in order to ensure that all dust is truly removed from the work area, must be able to extract it directly to the source before it disperses, passing through the sander itself.

Therefore, the first feature to check is that extracting is done centrally and at the same time as sanding to ensure the highest quality of workmanship.

The second point, on the other hand, concerns the choice between fixed or mobile extract system.

Deciding which is best depends on several factors:

- the size of the work area

- the needs of the company

- the extraction frequency

- any structural limitations

The supplier has different tasks:

- to carefully study the floor plans of the area in order to recommend the best industrial dust extraction systems for the company

- to understand where to install them

- how to position them to optimise space.

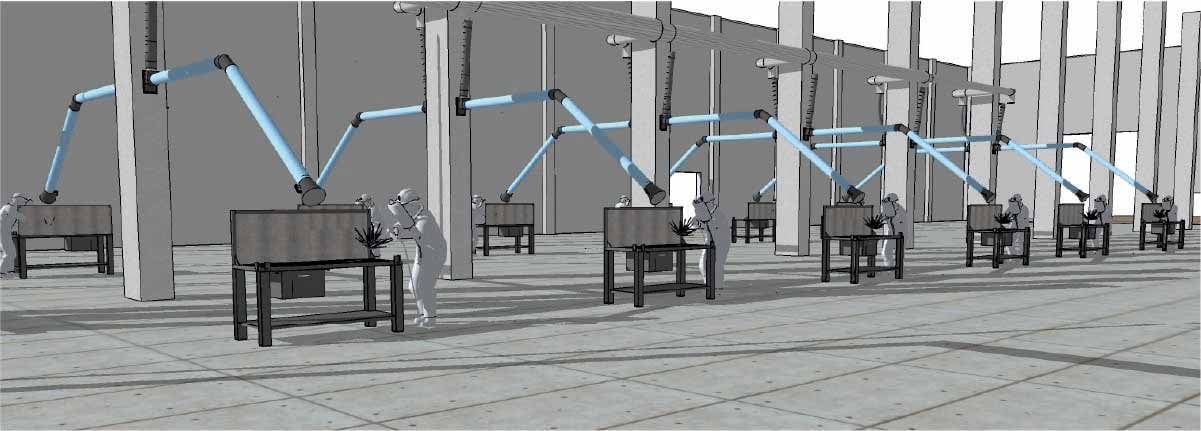

In general, fixed systems are ideal when sanding takes place in a limited area of the company, with a fairly high frequency.

These systems can include arms, power units or wall panels to connect the extraction pipe and centralise extraction with a high-pressure turbine positioned outside the working area.

This video shows the DTE, a WORKY-signed multifunction power pack for sanding dust extraction, in action.

Mobile systems are very manoeuvrable and easy to move from one area to another, ideal for those seeking maximum flexibility by not having a dedicated sanding area. The models range from compact to turbines with lateral channels that can work 24/7.

Choosing the right system means meeting the needs of the company without slowing down the work of technicians, thus ensuring maximum productivity while at the same time safeguarding the safety of personnel.

WORKY provides a wide range of industrial dust extractors to suit each individual need.

Our technology solutions are in line with Industry 4.0 standards and regulations, giving the opportunity to take advantage of all tax benefits to companies that decide to implement them.

Whether you are looking for a mobile or stationary dust extraction system, our experts are available to create a customized, tailor-made project: book a free, no-obligation consultation to discover the solutions best suited to your company's needs!