Every day, cars and motorbikes repair shops generate harmful gases that, if not removed immediately, can cause damaging effects on Technicians.

Every day, cars and motorbikes repair shops generate harmful gases that, if not removed immediately, can cause damaging effects on Technicians.

Gases are produced by vehicle mufflers, while engines are running during repairs.

When it comes to choosing an extraction system and its extraction arm, it must be taken in consideration that in a workshop usually Technicians work on different types of vehicles: cars, trucks, motorbikes and agricultural machinery.

Car workshop extraction arm: what it is and what it is used for

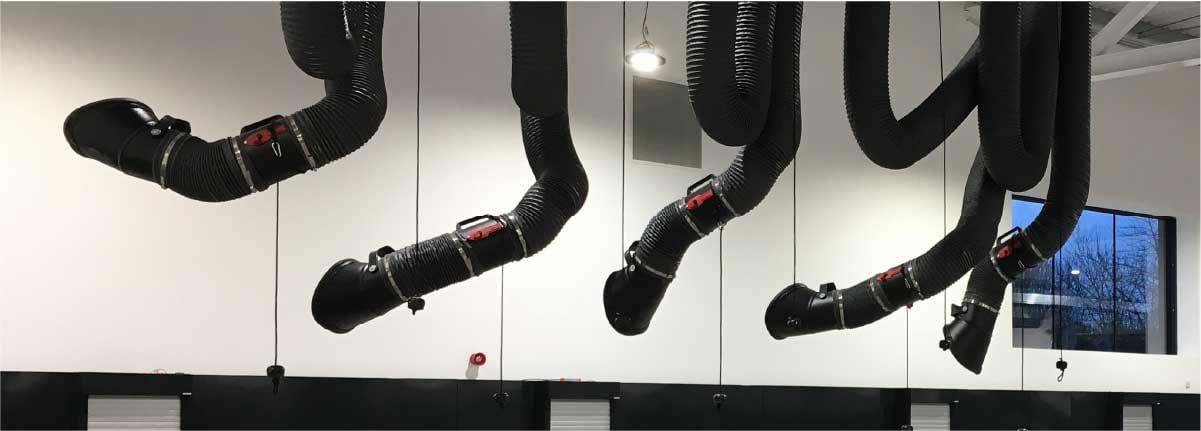

Touchless technology is a cutting-edge, versatile and high-performance solution that not only ensures maximum safety for workers, but also makes the workshop an innovative and modern place.

Vehicles are often left running during maintenance activities, expelling harmful fumes and gases. The suction arm, the models of which vary according to different needs, is a crucial component in workshops.

Arms connected to a vacuum cleaner help capture harmful substances directly at their source. This means that the gases are sucked up as soon as they are generated, thanks to the help of an arm whose 'mouth' is positioned directly at the source: the vehicle's exhaust pipe, thus preventing them from spreading into the surrounding environment.

This is vital to keep the work area free of pollutants and prevent long-term health problems among workers, such as respiratory diseases or allergies.

Various laws and regulations require workshops to maintain air quality standards to protect workers' health; in Italy, for example, this is law 81 of 2008. The installation of a proper extraction system is therefore a requirement not only for health and safety, but also for legal compliance.

Furthermore, being in compliance with air quality regulations improves the workshop's image and can lead to greater customer confidence. A workshop that complies with environmental and safety standards is often seen as more professional and reliable.

The importance of the Touchless system

Exhaust gas extraction in car workshops is not only crucial for health and safety, but also plays a significant role in increasing the workshop's operational efficiency. Let's see how.

Reducing downtime

An effective exhaust gas extraction system reduces the time needed to ventilate the work area. This means that vehicles can be worked on more quickly and in succession, without the need for long pauses to remove harmful gases, leading to increased productivity.

More comfortable working environment

An exhaust-free working environment is more comfortable for mechanics. Greater comfort can result in greater concentration and fewer errors, improving work efficiency and the quality of service offered to customers.

Improving workers' health

Reduced exposure to exhaust gases decreases the risk of health problems among workers, which in turn can lead to reduced absenteeism. Healthy workers are able to maintain a consistently high level of productivity.

Relying on an experienced supplier who can advise on the best type of system to install is the best choice for making good investments.

WORKY technicians can develop customised projects, tailor-made to the needs of each individual customer, analysing each reality in depth and then studying ad hoc solutions.

If you are looking for a specific extraction arm for your workshop or would like to install a gas suction system from scratch, do not hesitate to contact us: our experts are at your disposal for suggestions and advice!