Within a modern and a high-tech workshop, in order to achieve the maximum level of operativity and efficiency, plus to avoid any waste and downtime, modern dispensing systems have to be considered as a “must have”.

Within a modern and a high-tech workshop, in order to achieve the maximum level of operativity and efficiency, plus to avoid any waste and downtime, modern dispensing systems have to be considered as a “must have”.

In today’s article, we discuss about this topic. Read more to discover the most innovative fluid and energy dispensing solutions available on the market!

What are fluid and energy dispensing systems used for in the workshop?

Within any workshop or repair center, the main goal is to guarantee fast, efficient and accurate processes, reducing costs and avoiding waste of resources.

Not only the problems related to exhaust gases, which need specific extracting systems to be removed from the working area, but also the transfer of oils and fluids storage tanks to the point of use, and the flow monitoring, can be complex processes to deal with, involving a lot of time and resources too.

Among the essential workshop equipment, it is therefore impossible not to consider the systems dedicated to the replacement of technical fluids such as oil, antifreeze, window washer fluid, water and compressed air.

Having a very modern system involves several benefits:

- modern systems reduce dispensing time since the operator has not to leave the working area when changing the oil

- material costs reduce significantly, thanks to the possibility of buying more lubricants

- dispensing systems can be integrated with monitoring systems, which avoid waste and improve inventory management

Moreover, the most efficient and and correctly sized systems, according to the different needs, allow to optimize the space occupied by the equipment, making the work area tidy and clean. This aspect is often underestimated, while has a great impact on the workshop productivity.

It is important that operators can move freely and without hindrance and that they have everything they need at hand.

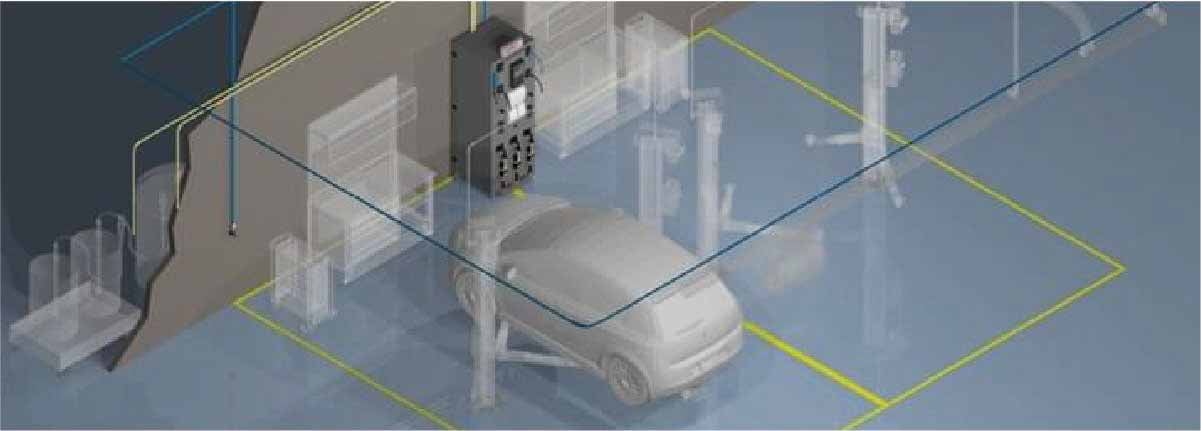

When it comes to fluid and energy distribution systems in the workshop, the most modern and efficient solution is multifunctional workstations.

Multiservice columns allow to have both the distribution of fluids and electricity, without the need for additional utilities and with the possibility of serving multiple locations at the same time.

The most advanced workshop oil dispensers can then be integrated by a computerised management thanks to QAM, an advanced monitoring system for technical fluid delivery in the workplace.

What is a fluid dispensing monitoring system?

Two of the biggest problems related to the use of fluid dispensing systems are:

- waste

- Failure to invoice for oil purchase

Every year, both of these factors cause severe losses of income to workshops and repair centres, which can be avoided by using the latest technology.

A management tool such as the QAM is equipped with solenoid valves with digital meters on the oil distribution lines and a computerized system that manages the data on each fluid dispense.

Thanks to QAM it is possible to:

- reducing polluting waste

- avoid waste and shortages

- keep costs down

- increase your profits

- comply with environmental protection standards

Multifunctional columns by WORKY

WORKY has designed 3 multifunctional oil dispensing systems for different types of workshops.

The fluid and energy dispensing control unit can be used in two different working areas, equipped with:

- up to 3 fluid reels from 1/2" up to 10 m long

- up to 2 cable reels or for distribution of compressed air or water

- 2 industrial electrical sockets

- 2 civil electrical sockets

A self-supporting metal structure designed to house a maximum of 4 or 6 reels for the distribution of fluids; being double-sided, can serve two working areas placed opposite each other.

Both the middle area and the bottom area have 2 drop collectors with a grill and emptying valve.

The most complete solution for the distribution of both technical fluids and energy in the workshop to house up to 8 reels for fluids and two reels for energy distribution.

The structure is designed for the connection of a hose reel for the extraction of exhaust gases and a work bench to be housed under the drip tray, in order to take advantage of all the available space.

Set up for connecting a hose reel for extracting exhaust fumes that can be provided with a work bench to be housed under the drop collector to fully exploit all the available space.

WORKY technicians, through an in-depth analysis are able to develop customized projects, studying ad hoc solutions, tailored to customers needs.

If you wish to learn more, take advantages from a free session with one of our experts: book it now!