Choosing the best exhaust gas extraction system for the workshop depends on several factors and, above all, on the needs of the business.

Choosing the best exhaust gas extraction system for the workshop depends on several factors and, above all, on the needs of the business.

In this article, we will look at all possibilities and give you some tips for making the right decision.

Exhaust fumes extraction systems: models for different needs

When you decide to invest in a new fumes extraction system for your workshop, there are usually two reasons:

- you realise that you need more advanced and modern technology to safeguard the health and safety of employees and ensure a healthy working environment

- you want to improve the productivity and efficiency of the workshop through quick and easy-to-use systems

In order to achieve these goals, however, it is essential to make a conscious choice, analysing the workshop's needs and opting for the system that responds 100% to these requirements.

Here are some typical doubts that may arise:

- Is it better to opt for a fixed or mobile system? Underfloor or stand-alone?

- Is the choice of a touchless system ideal? What are the advantages?

- What dimensions should the extractor, nozzles and pipes have?

- Where do I position the system in the workshop?

The answers to these questions depend on:

- the frequency of use

- the type of vehicles handled

- the number of workstations

- the size of the workshop

Let's go into more detail in the following paragraphs!

How to choose the right type of exhaust gas extraction system for the workshop?

To answer this question, we must first understand what the workshop needs, whether gas extraction is carried out regularly or occasionally. In the first case, fixed and sliding systems are ideal because they are easy to operate and provide high extraction power.

Fixed systems are usually used in small workshops or where vehicle maintenance takes place in a well-defined area and there is therefore no need to move these systems. Sliding systems, on the other hand, are useful when the working area is large and the areas dedicated to vehicle maintenance are far apart.

In lack of space, therefore, it is optimal to opt for fixed systems such as hose reels, minisets or underfloor systems, which have the advantage that they can only be pulled out when they need to be used, thus minimising clutter.

Instead, installing a sliding system such as the touchless articulated arm, which eliminates the need for specific nozzles and adapters as it does not come into contact with the vehicle exhaust, is a solution that is very flexible and offers significant cost savings as well as an equally significant increase in efficiency.

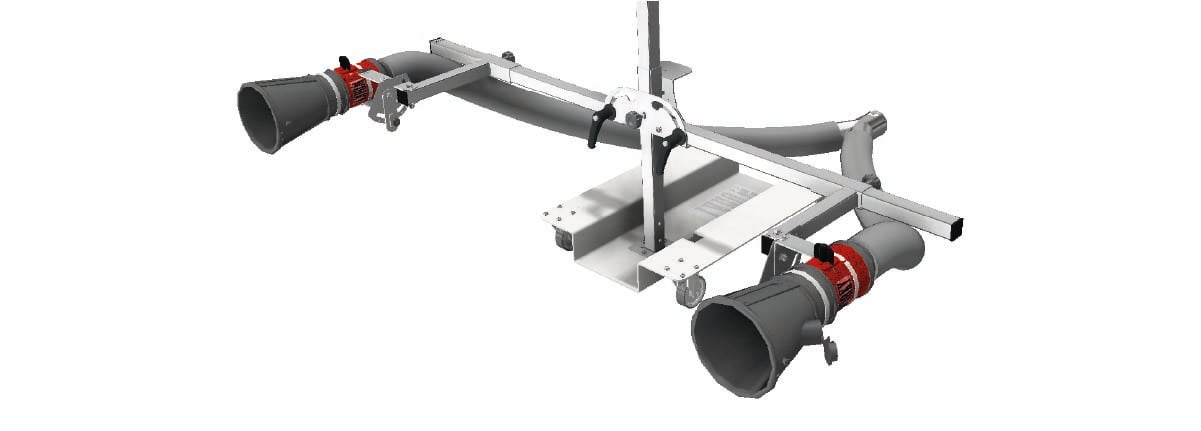

Mobile systems, on the other hand, are recommended when extraction is an extra-ordinary activity and there is therefore a need for a functional, but more cost-effective solution.

Another element to be assessed is the type of vehicles treated

Passenger cars, motorbikes, heavy duty vehicles, agricultural vehicles and trucks are very different and the choice of extraction system must take this into account.

Heavy duty vehicles produce a greater volume of gas than passenger cars. It is therefore necessary for the system to have the appropriate structure and dimensions to carry out the exhaust-gas extraction operations in the best possible way:

- the fan power needs to be in line with the gas extraction requirements

- the piping must be the right size and resist very high temperatures

- the nozzles must be perfectly adapted to the type of vehicle being treated

The situation is very different when it comes to motorbikes because workshops often try to adapt the extraction system to two-wheelers as well.

.png?width=500&height=500&name=Add%20a%20heading%20(5).png)

However, there are now specific solutions available for motorbikes, which are developed for different exhaust pipes than those of cars (such as double exhausts, undertail exhausts, underbody exhaust, multiple exhausts and oversized silencers due to the presence of the catalytic converter) and which take into account the fact that repairs to these vehicles often also take place on the stand or on the motorcycle lift.

It is also important that the systems fit in with the size and design of the workshop

Although this element is often underestimated when considering the purchase of an exhaust fumes extraction system, it is crucial to ensure maximum efficiency.

It is important to rely on an expert supplier who knows how to advise and design the best solution to allow technicians to always have the equpiment at hand, while avoiding excessive clutter that would not facilitate operations.

This requires a careful preliminary analysis of the building in order to identify and anticipate possible problems and to understand which options are preferable, also interfacing with architects and engineers to ensure a perfect integration of the systems.

Our 3D drawing and rendering service of the system is a huge advantage during the design phase; in this way, you have a realistic overview of the end result before making any decisions.

WORKY, in addition to the highest quality of the products offered, guarantees the presence of specialised technicians who design each exhaust system according to the workshop's needs.

In fact, customisation is one of WORKY's strong points to guarantee the highest levels of productivity, safety and integration of the systems in the work areas.

If you have any questions or would like to start designing your own system, do not hesitate to contact us: book a free, no-obligation consultation with our experts!