Exhaust gases contain a number of substances that are harmful to human health and can cause both minor discomforts and more serious problems. For this reason, legislation makes it mandatory to have extraction systems that remove exhaust gases from workplaces.

Exhaust gases contain a number of substances that are harmful to human health and can cause both minor discomforts and more serious problems. For this reason, legislation makes it mandatory to have extraction systems that remove exhaust gases from workplaces.

In this article, we would like to provide some tips for choosing the best gas extraction system, depending on the workshop's needs. Read on!

What types of extraction systems exist on the market?

Fixed systems, sliding systems, underfloor systems and mobile solutions are the main types of systems that can be installed today.

To choose the most suitable one, several aspects must be considered, related to:

- workshop dimensions

- type of vehicles treated

- number of workstations

- the needs of technicians

Below are the topics we will cover in the article; you can skip to the one you are interested in by clicking the corresponding link.

- Why install an exhaust gas extraction system

- The types of systems to choose from

- Extraction systems and ranges

- How to choose the best system

Why install an exhaust gas extraction system?

Exhaust gas extraction systems are essential, as well as mandatory, in all workshops.

Exhaust gases, being composed of fine dust, need to be extracted directly at the source and evacuated to the outside, where potential damage to human health is minimised.

This creates a healthier and more efficient working environment, as modern systems make operations simpler and faster, enabling technicians to complete more tasks in less time.

The targeted choice of the type of system to be installed in one's premises, therefore, guarantees at the same time:

- The effective extraction of exhaust gases

- Compliance with regulations

- Space optimisation

- The efficiency of the workplace

Furthermore, an optimal configuration saves on the installation costs of the system itself.

The types of systems to choose from

It is essential to identify the right sizing and the best configuration in relation to the workshop's operational and logistical needs. Let's have a look at which solutions are the best suit for each situation.

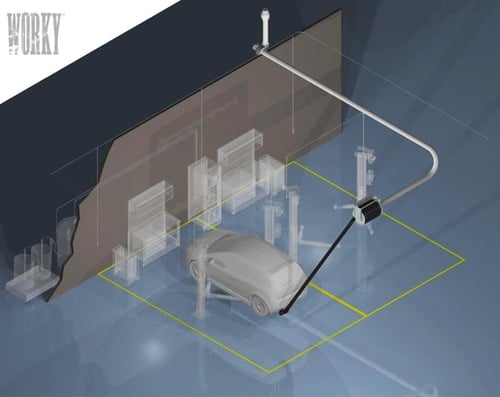

Fixed systems

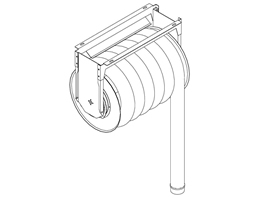

Fixed systems are ideal for extracting exhaust gases in small workshops. These systems intercept exhaust gases at the source by means of flexible hoses equipped with a nozzle, and then convey them to a fixed pipe system that expels them outside the workshop. To minimise space requirements, the hoses can be mounted on reels fixed to the wall or ceiling at the back of the working area.

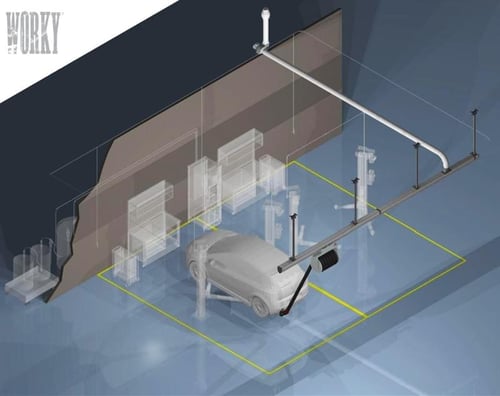

Sliding systems

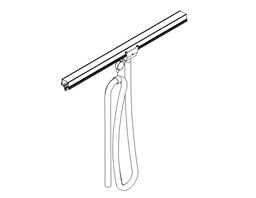

Sliding systems maximise the efficiency and optimise the installation costs of fixed systems and are particularly suitable for large workshops. In these systems, in fact, sliding hose trolleys and sliding hose reels run on a special aluminium extraction rail and can therefore reach even distant locations without any problems.

Sliding exhaust gas extraction systems offer:

- optimised costs, because sliding elements can be shared between stations

- great flexibility of use, as sliding elements can be moved where needed

- more space in the workshop, because when not needed the sliding element can be moved to another work area

- adaptability to any muffler, thanks to a wide range of nozzles and the innovative TOUCHLESS arm which, since it does not come into contact with the exhaust pipe, is a universal solution that does not require specific nozzles.

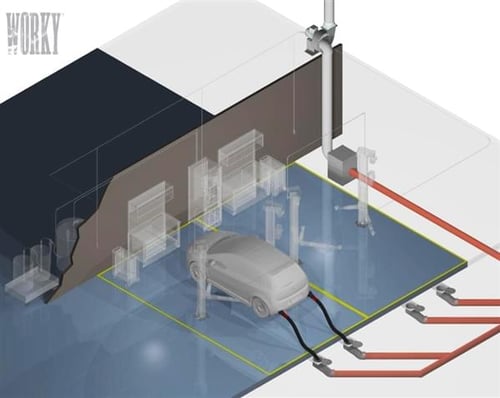

Underfloor systems

As in the previous configurations, exhaust gases are intercepted and conveyed in a pipe system, which, however, is housed under the floor instead of on the walls of the rooms.

These are concealed extraction systems: this means that the pipes connecting to the exhaust gas extractor are partly positioned under the floor and terminate in traps from which the flexible hose and nozzles are extracted.

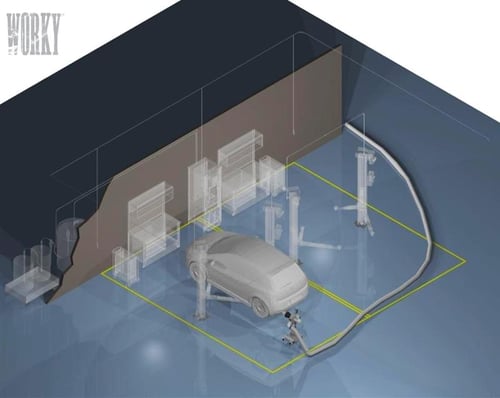

Mobile Systems

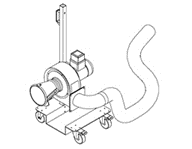

Mobile systems are the most flexible solution, suitable for small workshops requiring less frequent and more isolated applications. These extraction systems include mobile units mounted on wheels that can be easily transported to different work areas. The units are connected to flexible hoses to extract exhaust gases outside the workplace.

Here are some advantages of mobile systems:

- do not require permanent installation, as they have no fixed components

- do not require declarations of emissions, thus allowing less paperwork that lightens company administration

- they guarantee considerable operational flexibility, as they have no dimensional constraints and can be transported by a single person

- require very little maintenance due to the simplicity and reduced number of components involved

Extraction systems and price ranges

When it comes to establishing a quote for the installation of an exhaust gas extractor, several variables need to be considered:

- the number of workstations, since the more workstations there are in the workshop (i.e. the more vehicles are serviced at the same time), the greater the suction power is required

- the characteristics of the building, for example when - for spacing optimisation reasons - it is not possible to install external systems and an underfloor system is opted for

- the level of customisation required, i.e. the need to modify standard models or the creation of new models to meet different business needs

Each installation, in fact, is unique. When relying on a capable supplier, an in-depth study and, in some cases, an in-person visit to the working area are organised in order to determine in concrete terms how best to proceed, including discussing the feasibility from a structural point of view with engineers and architects.

Simple systems

Among the most economical extraction systems we can find the stand-alone systems, designed for smaller service centres. No real installation is needed: they are portable gas extraction systems that can be easily transported from one place to another. Four models of are usually offered:

- for cars

- for vans

- for motorbikes

- for trucks

Such an extractor fan avoids the need to install a roof chimney.

Medium range systems

Medium range systems

Exhaust gas extractors for workshops with mid-range prices are the fixed systems, suitable for medium-sized workshops with few workstations and concentrated in a limited area.

As explained above, a fixed system is realised with a permanent installation: nozzle attached to vehicle exhausts extract gases and, through reinforced rubber hoses, transmit them to galvanised pipes. The galvanised pipes end in a roof chimney and are designed to evacuate the gases without leaks.

High-end systems

Despite being in the higher price bracket, sliding systems are among the most popular in large workshops due to their extreme flexibility and convenience.

In fact, the sliding elements allow easy access to all workstations where the major emissions take place; not only that, when not in use, the sliding system remains suspended above the work area without interfering with the operators' activities.

How, then, to choose the best exhaust extraction system?

How, then, to choose the best exhaust extraction system?

The advice is to opt for the extraction system that best suits your company's needs and, above all, rely on our technical experts, who will actively listen to you and propose the best solutions for your budget.

Moreover, thanks to a photorealistic rendering, it will be possible to visualise the layout of spaces and volumes to get an idea of the final result and to be able to assess all that is needed for a perfect integration of the systems with the design of the environment, the spaces, the types of vehicles handled, and the customer's needs.

At WORKY, we specialise in creating solutions for the automotive sector and provide state-of-the-art extraction systems that significantly improve work quality and workshop productivity.

It is precisely because of the high quality of the products we offer and our customer focus that we have partnered with leading vehicle manufacturers, producing systems that live up to their standards of excellence.

We are constantly working to make business processes more efficient and innovative, developing customised projects tailored to the needs of each individual customer.

Qualified after-sales personnel are experienced not only in handling unforeseen events on site, but also in the phase preceding assembly.

Thanks to our dense network of WORKY dealers in more than 80 countries, we can assist our customers with every need: book a free consultation!